OUR CURRENT MASTERS

Our handcrafted dice are not just a product, but a labor of love that begins with raw materials and ends with a magical creation.

Each step of the process is imbued with our craft, resulting in unique and captivating dice that are not without flaws, but are a testament to the hand-made process

For full transparency we‘re offering an overview of the design decisions and little flaws that each of our master sets entail.

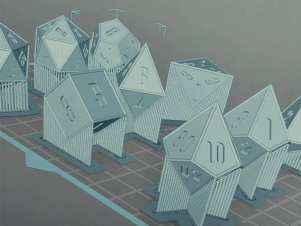

Master v.2 (new)

This is currently is use

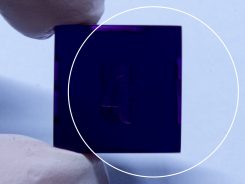

Design: Our logo (the eye) is only featured on D6 in sets, single D20 and D20 chonks. We use a condensed sans-serif font for better legibility and improvement the sharpness of the dice overall.

Flaws: Nicks and micro scratches, shallow #2 on D6.

Master v.1 (old)

There’s only a hand-full left in the shop

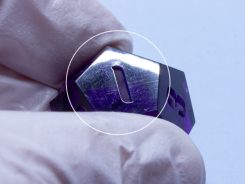

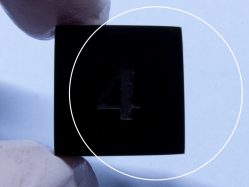

Design: this set features our logo (the eye) on the highest number of every die and uses a serif font.

Flaws: D6 is skewed, some numbers are drooping, points/corners are not sharp, micro scratches and nicks.

TAKE A PEEK BEHIND THE SCENES

How are our dice made? Here’s a quick run-down of the steps we go through in order to create these magical pieces!

DESIGN & PRINTING

Our dice masters are designed and 3D modelled from scratch. We use Illustrator and Houdini for our digital creations. The finished files are printed with an SLA printer for detailed results.

SANDING

MOLD MAKING

The finished master set is used to create the molds we use to cast our resin dice. This step needs to be done again and again, because molds will degrade over time, resulting in matte/faulty dice.

CASTING

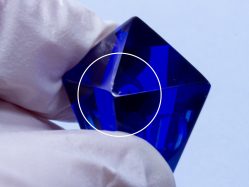

We exclusively use high quality resin and a wide range of (cruelty free) additives. Combined with our experience and techniques we‘re able to create unique sets that last.

POLISHING

After casting, the dice need to cure properly before we can proceed with polishing. We use a combination of polishing compound and special sanding paper to achieve a shiny finish.

THE FINAL TOUCH

In our last step, we ink the numbers acrylic paint for better legibility.

Once done, the set is carefully stored away in a black velvet bag to shield them from hard lighting.